Brief Description of the Chiller:

The AQUAFORCE Vision 30KAV air-cooled chiller, equipped with Greenspeed™ intelligence, is the latest innovation from Carrier Corporation. Featuring the advanced Touch Pilot™ control system, it provides real-time operating parameters, making it intuitive and user-friendly. The 30KAV also includes smart energy monitoring that delivers data on real-time electric consumption, cooling energy output, and energy efficiency ratios, both instantaneous and seasonal.

This chiller is an ideal solution for commercial and industrial applications, offering reliability and top-tier performance in temperatures ranging from -20°C to 55°C.

Fig.1 : Aquaforce vision 30KAV Air cooled chiller

Summary of Features:

- Outstanding performance

- Low noise levels (90dB(A))

- Versatile for various applications

- Smart connectivity and intelligence

- Environmentally responsible

- Easy installation and maintenance

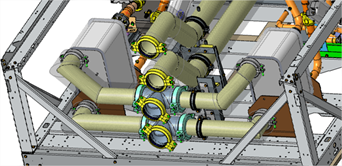

Fig. 2: 30KAV parts

30KAV Maintenance:

With its advanced components and cutting-edge features, maintaining the 30KAV is essential to ensure optimal performance. Proper maintenance saves energy, reduces downtime, and extends the life of the chiller. Neglecting maintenance leads to increased operational costs and unplanned outages. To maximize the benefits of this innovation, it’s crucial to establish a robust maintenance program.

At Mandilas, we’ve identified key preventive maintenance practices that can ensure the 30KAV runs efficiently and reliably.

Daily Chiller Log:

Maintaining a daily log of the chiller’s operating conditions is the foundation of an effective maintenance program. This log captures essential data such as temperatures, pressures, and alarm histories, helping technicians identify potential issues before they escalate. Monitoring daily trends allows for timely preventive maintenance, reducing the risk of costly unplanned outages.

Condenser Coils and Evaporator Tubes:

The performance of the 30KAV heavily relies on clean condenser coils and evaporator tubes. Contaminants like scale, mud, algae, and other impurities reduce heat transfer efficiency, increasing thermal resistance. Monitoring the temperature differential (delta T) between entering and leaving water temperatures is crucial. A rising delta T signals reduced efficiency and potential performance issues. Regular cleaning of condenser coils (quarterly) and evaporator tubes (annually) prevent fouling and maintains optimal performance.

Refrigerant Charge:

Proper refrigerant levels are critical to the chiller’s cooling capacity. Maintaining the correct charge ensures that the compressor doesn’t overwork. Refrigerant leaks and moisture infiltration reduce efficiency and can lead to system failures. Keeping the refrigerant levels in check prevents unnecessary strain on the compressor.

Compressor Oil Analysis:

Annual oil sampling and analysis provide valuable insights into the condition of the compressor. High moisture levels in the oil or deviations from OEM specifications can indicate underlying issues. Regular oil analysis helps ensure the compressor operates at peak efficiency, and oil filters should be replaced when pressure drops exceed recommended levels.

Variable Speed Drive (VSD) Starters and Compressors:

Efficient operation of VSD starters and compressors relies on the proper calibration of safety sensors and control systems. Annual checks should include thermal scans of electrical connections for hot spots and insulation tests on compressor windings. These preventive measures reduce mechanical stress and extend the chiller’s operational life.

The chiller has heat

recovery and high-performance EC motors options, designed to meet all the requirements.

The 30KAV chiller is designed for use in the following applications: multi-residential,

green buildings, Industries, Data centers, hotels, hospitals.

Fig.3: Heat Recovery Option

At Mandilas, our team of mechanical Engineers specializes in all aspects of chiller maintenance, from design and installation to ongoing operation and troubleshooting. Whether it’s analyzing issues, optimizing performance, or identifying potential maintenance challenges, we are committed to keeping your Carrier chiller running efficiently.

For world-class cooling solutions and expert Engineering Services and Solutions, talk to us today.

Mandilas… committed to you!